Know the ins and outs of additive manufacturing Singapore

Additive manufacturing can be referred to as a fancy name for an industrial name given to the process of 3D printing. Through this process, one can produce three-dimensional objects through the deposition of layers. Through various computer technologies in additive manufacturing singapore helps create objects of perfect geometrical structures. These processes are quite different from the traditional methods used. In this process, the objects are made by laying down materials layer by layer. These processes are self-sufficient and do not require any other machine to get rid of the surplus material as traditional machines do.

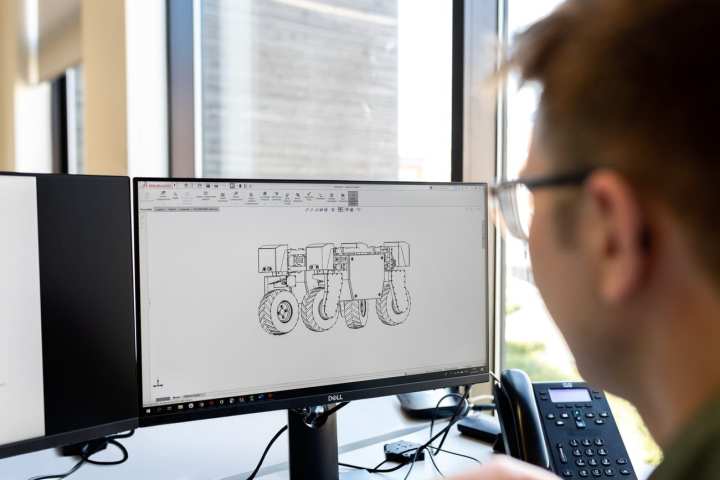

How are these machines used?

These machines are not very easy to be used and require a series of complex procedures. The processes used by additive manufacturing singapore have their set standards and are listed below:-

- the first process that produces 3D objects by laying down materials in powder form layer by layer with the use of an adhesive is referred to as binder jetting. Constantly moves along the X Y and- to facilitate the laying of these materials.

- the second kind of additive manufacturing is direct energy deposition, which can be used with various materials using a beam gun that constantly keeps moving along the horizontal axis.

- the third process in this series is referred to as metal extrusion. In this method, old polymers are extracted through the use of a nozzle that keeps moving horizontally as the bed keeps moving vertically. In this, the layers stick to each other through chemical agents’ presence or by controlling temperature accordingly.

- the fourth process in this series is powder bed fusion, which includes various to help melt fine materials. Whatever is left behind after this process is blasted away.

- through this sheet lamination process, one can create visually pleasing items by using alternate layers of paper and adhesive.

- through the process of vat polymerization, a kind of liquid is used to build up objects.

- the final process in this series is the wire arc additive manufacturing that requires robotic equipment to produce items.

This additive manufacturing process is extremely beneficial as it can create complicated objects accurately and generate very little waste. As the relic is Les, it can also be referred to as a cost-efficient method. The parts that needed to be reassembled from various sources can now be fabricated as a whole with the help of these processes.